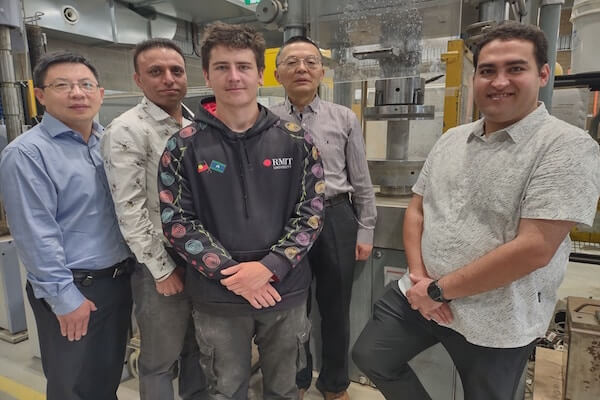

RMIT University’s research team has found a remarkable breakthrough, helping transform PPE equipment into reinforcement materials for strengthening structural concrete.

It will make use of around 54,000 tonnes of Personal Protective Equipment (PPE) waste that has been produced per day since the pandemic to instead increase the strength of concrete by up to 22 per cent, as well as improve its resistance to cracking.

Rajeev Roychand, the joint lead author of the research, has called the results “heartening.”

“There has been considerable interest from the industry, healthcare companies, as well as manufacturers of PPE items,” he told Indian Link.

“This is particularly significant due to the high levels of PPE use in context of COVID. Also, a lot of the PPE items lay unused past their expiry date and need to be properly disposed off. Our research has a lot to offer in that scenario as well.”

The researchers from RMIT School of Engineering carried out three separate studies on the recycling PPE, in particular, rubber gloves, isolation gowns, and face masks. Their research has provided empirical evidence that these PPE items can be used to increase the compressive strength and elasticity of concrete.

Pursuing a circular economy approach, the researchers have found a solution to the longstanding problem of recycling and disposal of PPE waste — something that has become more of a challenge due to the surging use of different kinds of PPE items during the pandemic.

The project has already got on board with the industry, with the RMIT School of Engineering team’s industry partner Casafico Pty Ltd. set to utilise this research in some of their projects. They are keen to collaborate with the healthcare and construction industries to further develop the research.

READ MORE: Australia-India Council research grants: Nine projects win support

Every month, about 129 billion disposable face masks are used and thrown away around the globe. This research could be a massive step towards providing a smart solution for this ever-growing pile of COVID-19 generated waste, noted first author Shannon Kilmartin-Lynch, a Vice-Chancellor’s Indigenous Pre-Doctoral Fellow at RMIT.

“This challenge will remain even after the pandemic is over,” Kilmartin-Lynch said. “Our research found that incorporating the right amount of shredded PPE could improve the strength and durability of concrete [and provide a viable solution to this issue].”

“As such, COVID aside, there is traditionally a huge quantity of PPE materials that end up in landfills. Plastics from the PPE turn into micro-plastics and end up in oceans, thereby endangering marine life and causing marine pollution,” Roychand added.

“Incinerating them [PPE items] is also not a viable solution. So, if they can be used in concrete, on the lines of what our research has come up with, it will provide a sustainable solution to this serious problem.”

For Roychand, who moved to Australia from Amritsar, this research is the ideal avenue for what he loves to do, that is finding engineering driven solutions to some of the most pressing challenges of the 21st century.

The team are currently looking for additional funding to come through, so the research effort can be expanded.

“Looking at the near future, me and my colleagues are busy trying to find more industry partners for adoption of their discovery and towards continuing teaching the next generation about concrete structures and building sustainability into the science of construction,” Roychand concluded.

READ MORE: How these scientists found sustainable solutions in single-cell micro-algae