Every year, 10 billion kilograms of coffee grounds is produced globally. In Australia alone, 75 million kilograms of ground coffee waste is generated annually – most of which goes to landfills. But what if this daily brew byproduct could be repurposed for something more ‘concrete’?

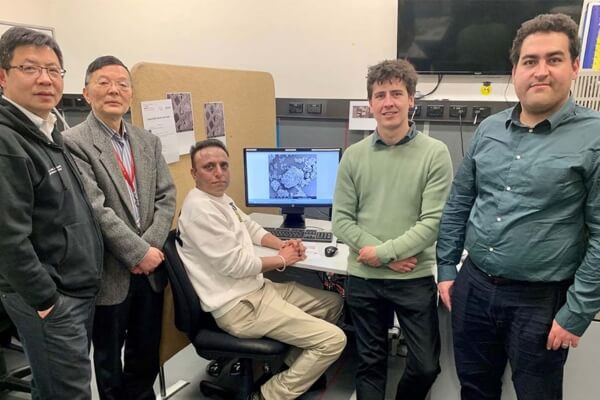

Researchers at RMIT University in Melbourne have discovered a groundbreaking way to transform spent coffee grounds into a key ingredient for concrete. By using coffee waste as a substitute for dwindling sand resources in infrastructure projects, these experts have found a sustainable innovation that not only reduces waste but also addresses the global shortage of construction materials.

The motivation behind this research was large amounts of organic waste ending up in landfills and contributing to high greenhouse gas emissions, RMIT Postdoctoral Research Fellow Dr Rajeev Roychand told Indian Link.

“As per the National Waste Report 2022 (updated February 10, 2023), about 6.13 million tons of organic waste ends up in landfills and contributes to 2.5% of Australia’s greenhouse gas emissions,” he added. “Our research group was discussing about shifting our focus to divert this waste from landfills and develop innovative solutions to transforming this waste into a valuable resource for different applications.”

Interestingly, this discussion happened over a cup of coffee.

“That’s where we decided why not start with coffee waste?” Dr Roychand shares about the study published in the Journal of Cleaner Production.

The innovation developed at RMIT University is now being used for the first time in a major infrastructure project, being laid into a footpath along a busy road in Pakenham as part of Victoria’s Big Build.

Dr Roychand explains how this is being done: “Coffee waste is roasted in the same way they roast coffee beans to bring out taste and aroma. The only difference being that we roasted the waste at an optimum temperature of 350°C and in the absence of oxygen. This process breaks down the organic compounds present in coffee waste leaving behind carbon-rich porous material, known as biochar. This biochar is further used to replace 15% of sand by volume, in concrete.”

Concrete made greener

The use of biochar from coffee grounds enhances the strength of concrete by 30%, researchers said.

“Biochar produced from waste coffee grounds at 350 °C temperature provides an optimum combination of pore structure, and carbon content that can absorb and hold water,” Dr Roychand explains. “So, when coffee biochar is mixed with concrete, its particles act like microscale water reservoirs distributed throughout the concrete. As the concrete sets and starts to harden, the biochar slowly releases the water it stored, rehydrating it when needed, thereby reducing shrinkage micro-cracking. This results in the improvement in concrete strength.”

The main challenge was finding the right way to treat the coffee waste without weakening the concrete. Maintaining the material’s strength and durability was key, and developing the ideal process to ensure this took time and effort.

“We started our research with using dried raw coffee waste into concrete. However, we observed a significant reduction in concrete strength. Coffee waste leaches out organic compounds that hinder cement reaction, thereby negatively impacting its strength development.”

The team then used the pyrolysis process, to break these organic compounds but preserve the carbon content.

“Typically, pyrolysis is carried out at higher temperature for the efficient thermal decomposition of organic waste. However, our focus was to minimise the use of energy. We started with pyrolysing at 500°C temperature and saw significant enhancement in concrete strength compared to that of the raw coffee grounds in concrete, but it was still lower than the control concrete, not containing any coffee waste. Since our focus was to minimise the energy consumption, we went for a lower pyrolysis temperature of 350°C and hoped that the lower decomposition could potentially help in improving the properties.”

And, it worked. “It was a blessing in disguise,” he adds.

Brewing a concrete future

Now, can coffee concrete be applied in large-scale construction projects like buildings, or is it better suited to smaller applications like footpaths and driveways, we ask.

Dr Roychand says it can be used in all types of outdoor concrete projects, such as footpaths, roads, concrete slabs, bridges, and so on. “However, for indoor environment, we need to test the concrete containing coffee biochar for its fire rating.”

This is part of their further research and development.

But for now, the team has conducted two successful trials of their coffee concrete and the response from the council has been encouraging.

“Our first trial was in collaboration with Macedon Ranges Shire Council, which was happy with the performance as it creates a potential for diverting a large amount of organic waste that the council handles. We also collaborated with Bild Group and Major Road Projects Victoria (MRPV) for another trial in Victoria’s big build projects.”

The researchers are now on track to commercialise this technology and make it a mainstream product, with advanced discussions currently underway with a company interested in taking this innovation to market.